Double(V)Press Fittings

Double(v) Press Fittings

The Rhinox Double (V) Press Fittings Systems is exceptionally quick, reliable and durable fitting assembly system and gives a strong and leak proof joint with good mechanical resistance for applications such as – Drinking Water, Gas, Heating and Solar Installations to Cooling Water and Compressed Air Systems. The resilience of the deformed seal rings ensures that the fittings are permanently and hydraulically leakproof. With corrosion resistance, stainless steel claws on the inside of the fitting giving high ensure tensile strength. Rather than the traditional methods such as welding and soldering, our quick connection methods Pressing and Insertion save lots of time.

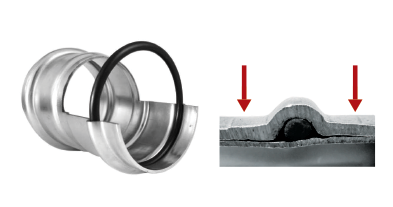

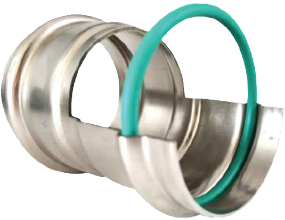

O-RINGS

The standard fittings for water and heating are fitted with EPDM O-rings. The type of O-ring which has to be used

depends on the application and the medium. This is why gas press fittings are fitted with HNBR O-rings. An FPM O-ring

has to be fitted for special applications, such as media containing oil or high temperatures.

depends on the application and the medium. This is why gas press fittings are fitted with HNBR O-rings. An FPM O-ring

has to be fitted for special applications, such as media containing oil or high temperatures.

Black EPDM

Green FKM

Yellow NBR

Advantage Of Installating

Double Press Fittings

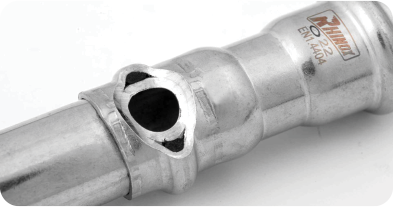

Mechanical Interlock

Wide range of Applications With its keen components, Rhinox system is highly resistant. An operating pressure of 2.5 MPa (25 bar) and above can be achieved.

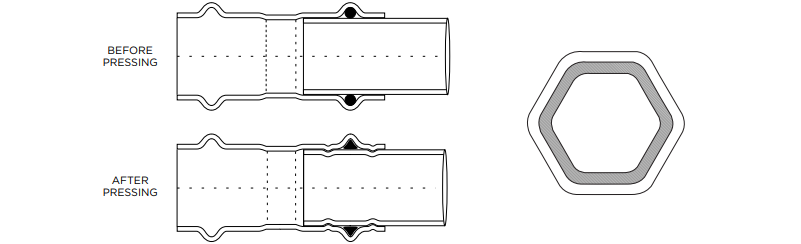

Pressing Profile

The connection provides a rigid coupling with excellent resistance to torsional forces. This is particularly beneficial when connecting mechanical threaded connections.

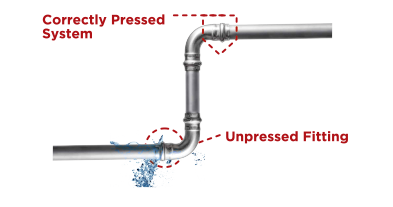

Smart Leak Detection

We ensure that the watertightness of a complete installation can be centrally and conveniently tested, as long as the installation is equipped throughout with Smart Connect Feature.

Material

Stainless steel press connectors are equipped with an extremely durable EPDM sealing element. The stainless steel pipes 1.4401 are hygienic and outperform on account of their efficiency.

Double Joint - 3 Point Press

The Rhinox fittings are designed to deliver minimal deformation to the internal shape of the tube they are connecting to, reducing turbulence in the flow of the medium being conveyed.

With Stand All Pressure

We offer the right solution for every medium. Two different elastomers can be employed in the press connectors: the EPDM seal, used mainly in water installations.

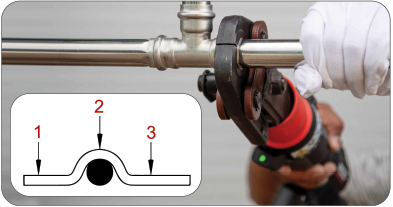

Joining Process

Rhinox double (V) press fittings technology is highly secure, the reason for this being that our press tools carry out 3 pressing points simultaneously. The joining process, is fully able to provide a long-lasting connection which is torsion proof and longitudinally force-locked. The connectors are pressed in a matter of seconds and permanently secure, without the danger of fire and time-consuming fire prevention measures. A lot of work stages, which normally cost time and materials, are no longer required. Instead, you can assemble an optically attractive installation without traces of soldering and too much effort.

SPEED

- Double Press Fittings are absolutely safe, cost-effective and time-saving installation method.

- Even time-consuming installations can be completed by cost- effective one-man assembly.

- Pressing without the risk of fire and time-consuming fire precautions.

+

RELIABILITY

- Computer-controlled, automated production delivers absolutely reliable results.

- Rhinox SS plumbing prove themselves in the most difficult working conditions.

- Through their stainless steel quality, pressing tools functionality, numerous pressure and leakage testing by our team.

=

MEASURABLE RESULTS

- Especially suitable for heating installation as well as closed cooling systems and compressed air systems.

- Very good long term characteristics even at high temperatures and pressure levels.

- The connection provides a rigid coupling with excellent resistance to torsional forces.

- A special thermal treatment creates a homogeneous material structure in the weld seams.

- RHINOX system press fittings provided with a black EPDM sealing ring (ethylene-propylene-diene) rubber.

- The resilience of the deformed seal rings ensures that the fittings are permanently and hydraulically leakproof.