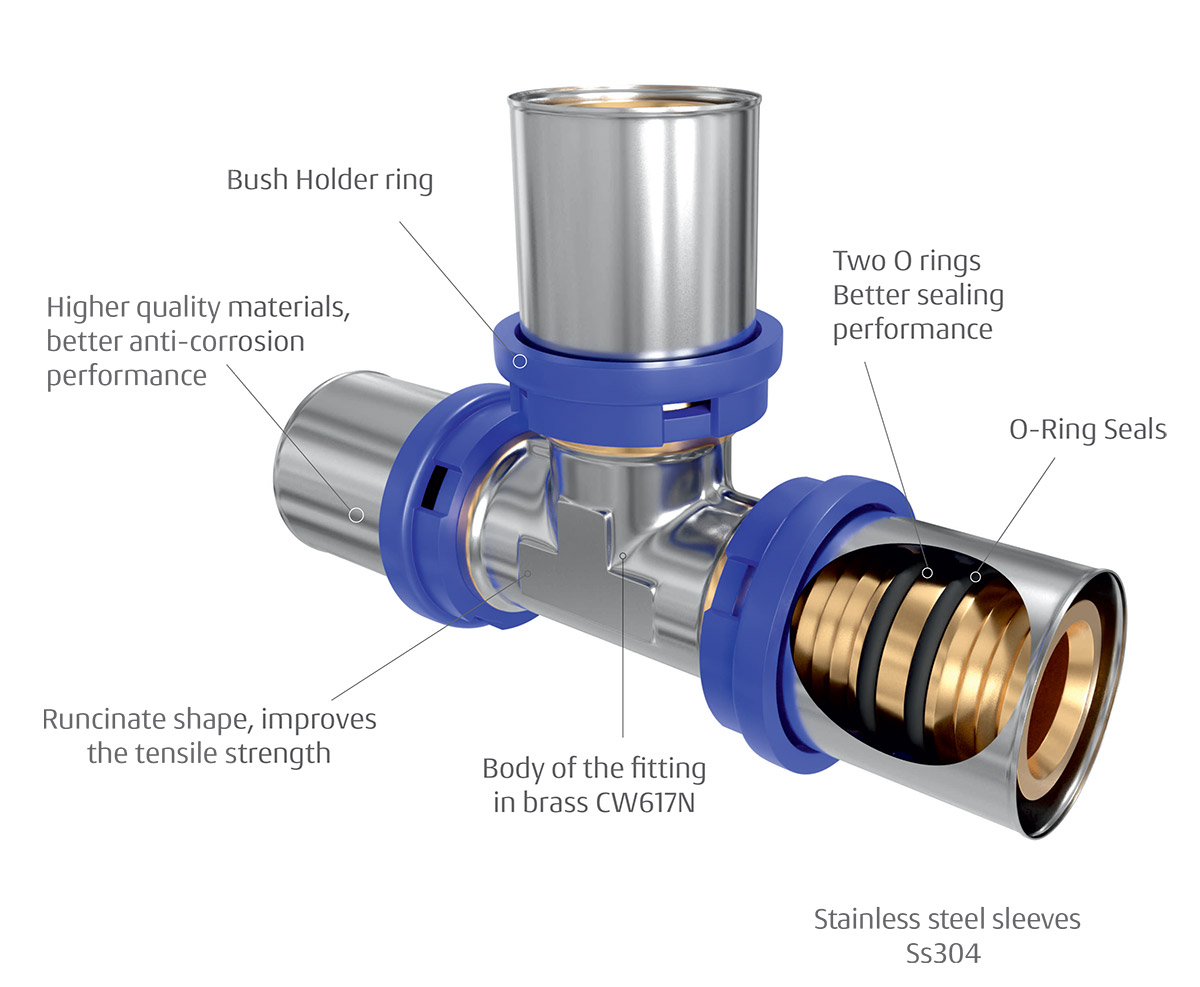

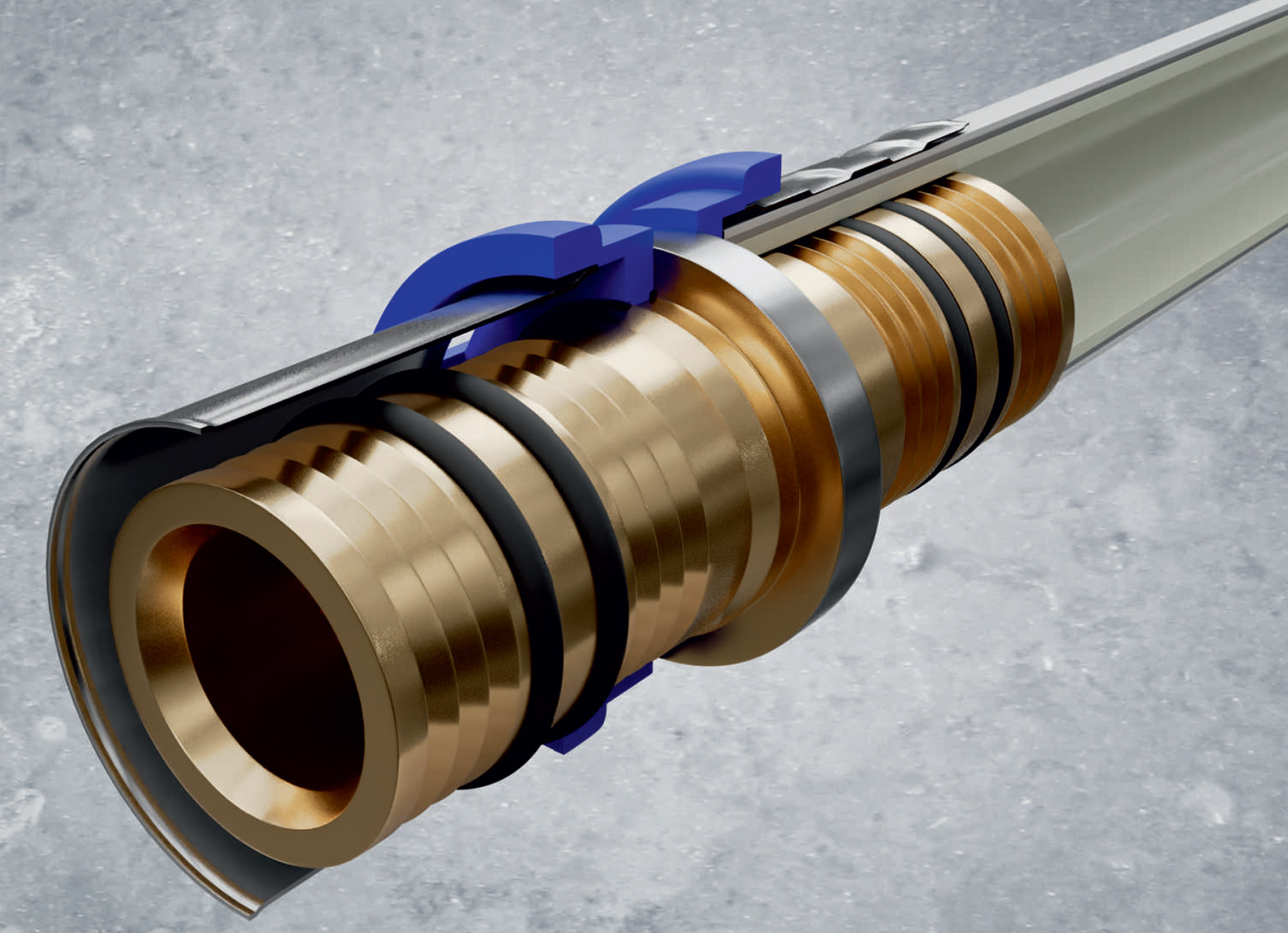

The body of the Rhinox press fittings is made of brass nickel. Note that the nickel plating only remains on the surface and does not have any contact with the fluid carried. The body comprises mainly two parts – one is visible while the other enters the tube. The latter one is referred to as the hose holder. It features a unique anti-slipping sawtooth profile and houses two O-rings that ensure a proper hydraulic seal.

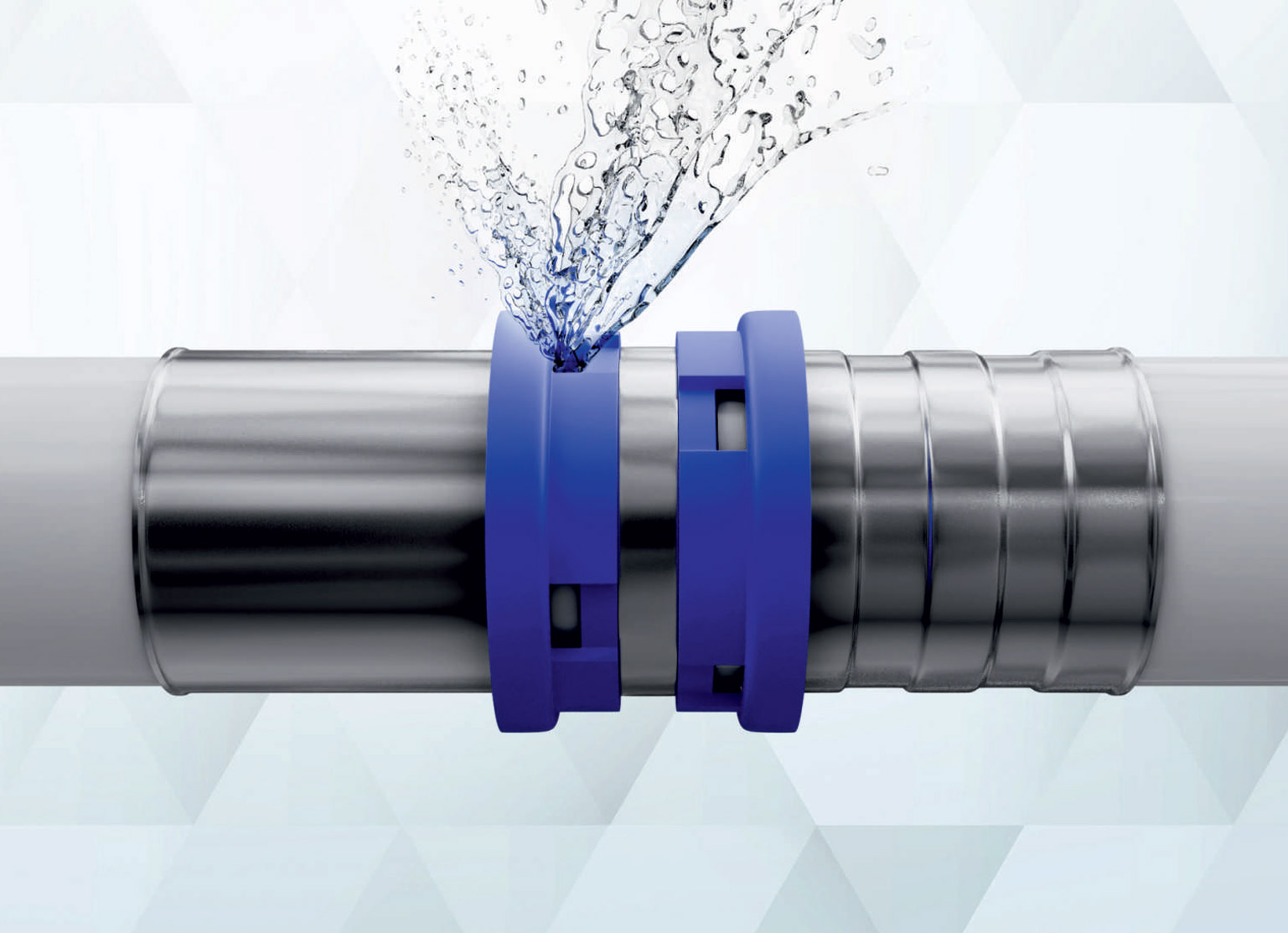

Each end of the fitting enters the pipe. The ends are equipped with two pre-lubricated EPDM O-rings. They ensure a watertight seal. Evidently, they can accommodate the different expansion rates of the materials used in the system. If the pressing is incorrect or incomplete, the fitting may leak visibly during the testing phase.

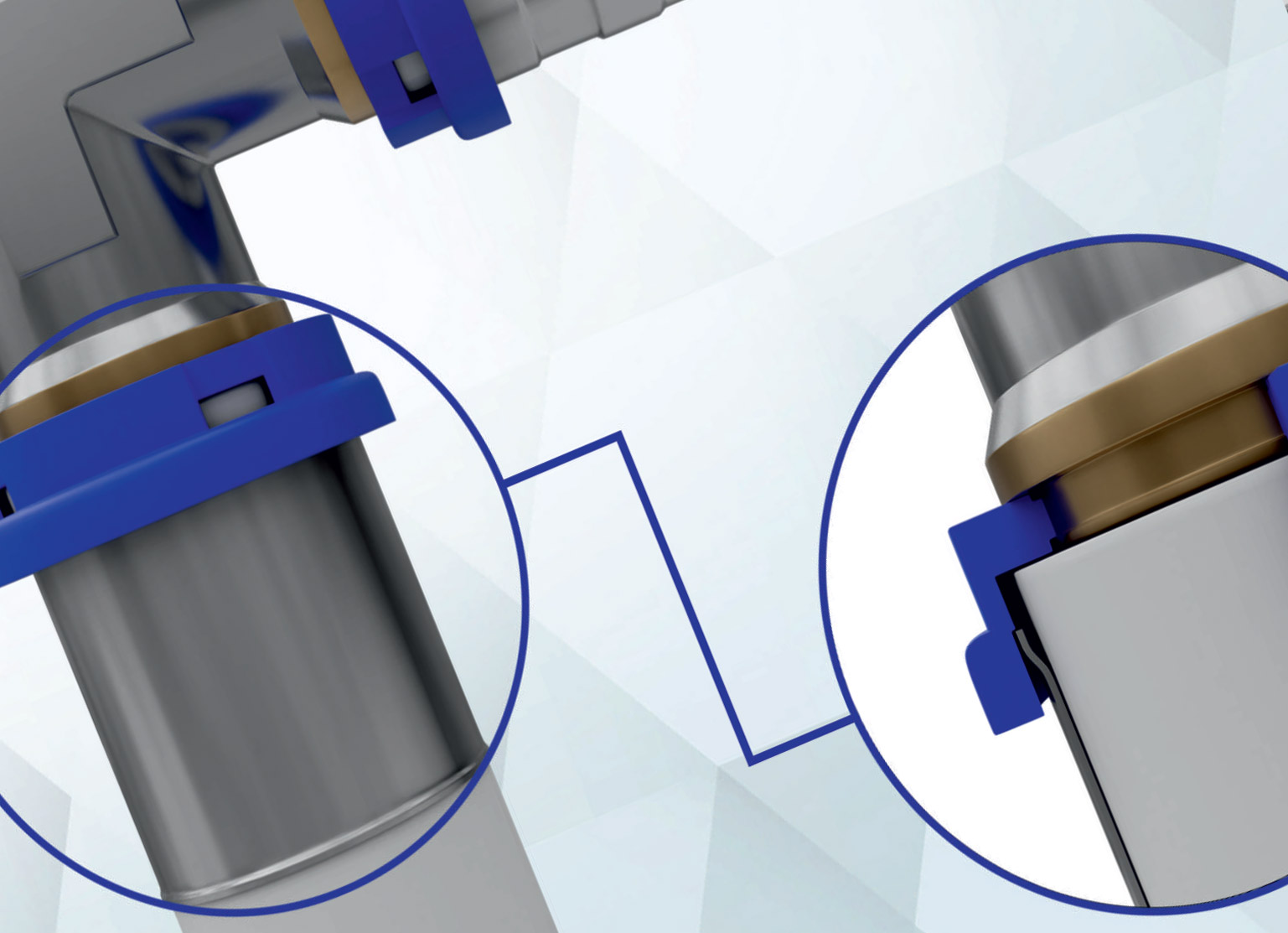

The prime USP of the Rhinox press fittings is that they feature a blue plastic collar that comes with sight holes. This feature facilitates proper installation. Through the sight holes, the installer will know that the pipe is inserted completely into the fitting before the pressing phase.

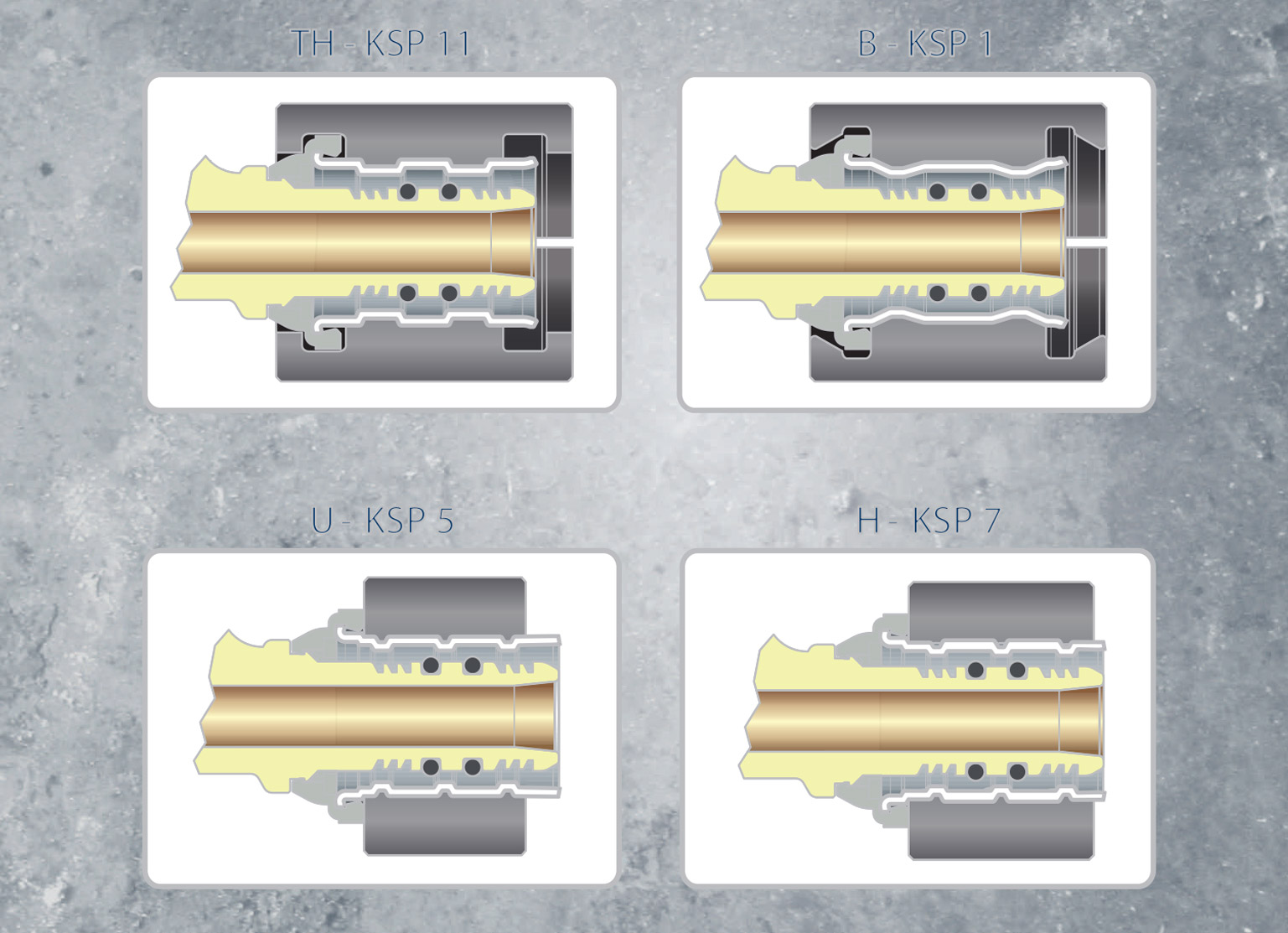

The AISI 304 grade stainless steel sleeve is marked with the thickness of the corresponding pipe, diameter, and the pressing profile, which are U, H, and TH. It is produced by a drawing process that ensures ~ 160 Hv hardness for safe and uniform pressing.

Rhinox-Wepit System has some excellent technical features. The following are the technical features of the Rhinox-Wepit System:

We have built a new design of brass fittings with the above features that offer stability and durability during demanding conditions. Seek consultation from us to learn more about our fittings.