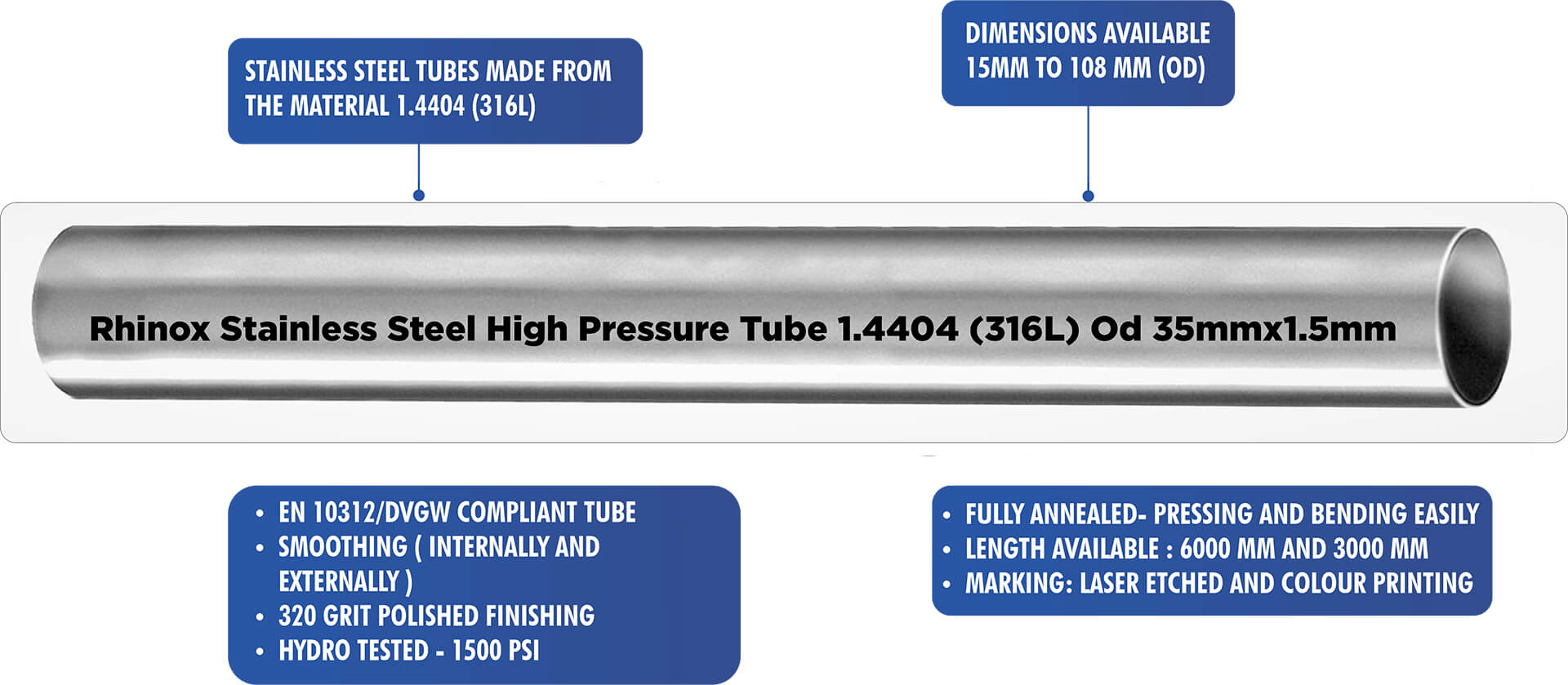

Our stainless steel pipes are manufactured with state of the art technology and are designed to achieve and sustain in harsh locations for various applications. Rhinox offers a multitude of high-quality tools as well to be utilized for pipework for both household and commercial projects. Build with Durable Quality Stainless Steel Material & Providing Strong Protection Without any Leakage Issues. Stainless Steel Pipes are Fully Resistant to Crevice Corrosion & Polluted Water. Precise properties of Pipes and Tubes produced, meet the most stringent requirements. A complete system of precision engineering & technology giving a seamless connectivity to pipes. Our pipes meets the industry standards in a wide range of sizes, forms, and alloys. Insulated pipes maintain stable temperatures, while PE coated tubes tubing provides protection from harsh elements.

| Normal Size | Outside Diameter (mm) | Wall Thickness | Dry Weight kg/m | Wet Weight kg/m | Valume l/m | Tube Length mm | 6m Tube Mass kg |

|---|---|---|---|---|---|---|---|

| DN15 | 15 | 1.0 | 0.351 | 0.484 | 0.133 | 6000 | 2.11 |

| DN20 | 22 | 1.2 | 0.625 | 0.928 | 0.302 | 6000 | 3.75 |

| DN25 | 28 | 1.2 | 0.805 | 1.321 | 0.515 | 6000 | 4.83 |

| DN32 | 35 | 1.5 | 1.258 | 2.062 | 0.804 | 6000 | 7.55 |

| DN40 | 42 | 1.5 | 0.521 | 2.718 | 1.195 | 6000 | 9.13 |

| DN50 | 54 | 1.5 | 0.972 | 4.015 | 2.043 | 6000 | 11.83 |

| DN65 | 76.1 | 2.0 | 3.711 | 7.794 | 4.083 | 6000 | 22.27 |

| DN100 | 108 | 2.0 | 5.308 | 13.81 | 8.495 | 6000 | 31.85 |

| Material | Carbon | Silicon | Manganese | Phosphorous | Sulfur | Nickel | Chromium | Molybdenum |

|---|---|---|---|---|---|---|---|---|

| EN 1.4404 | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 10-12 | 16-18 | 2.0-3.0 |

| Material | Proof Stress Rp0.2% N/mm2 |

Proof Stress Rp1.0% N/mm2 |

Tensil strenth Rm N/mm2 |

Hardness | |

|---|---|---|---|---|---|

| 1.4404 | min. 240 | min. 270 | 520 | < 95 | |

| 1.4404 | Carbon | Chromium | Nickel | Titanium | Molybdenum |

| min. | 16.0 | 10 | 0 | 2 | |

| Max. % | 0.03 | 18.0 | 14 | 0 | 3 |